Technology area

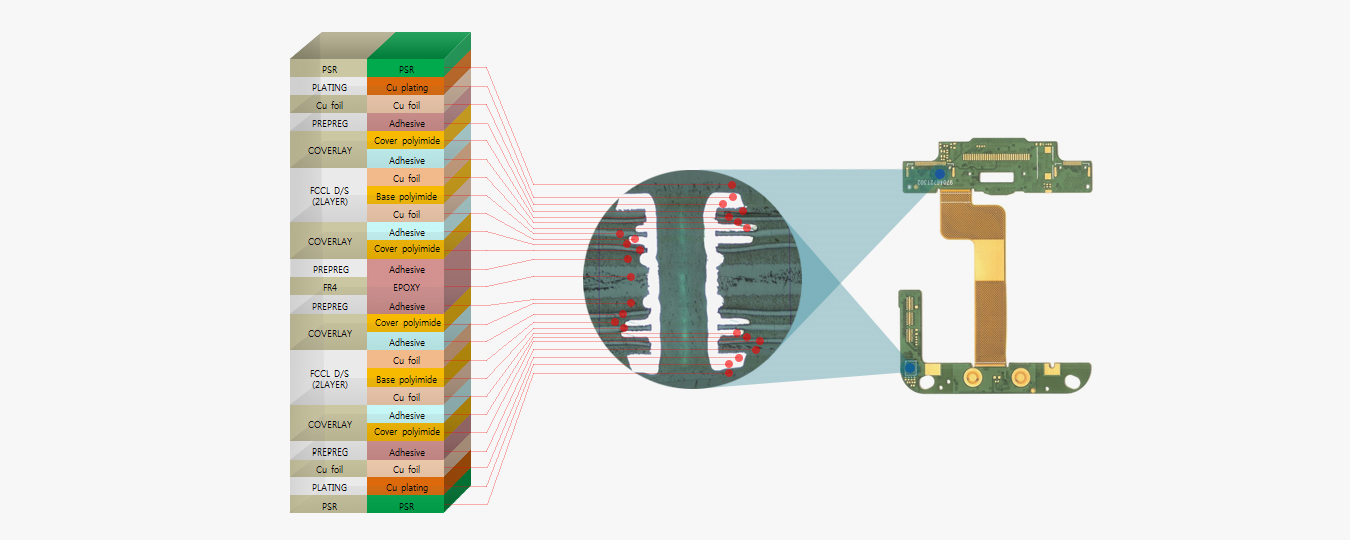

Structure of FPCBTECHNOLOGY DRIVEN ELECTRONIC COMPANY

- Build up

- Gloflex will become a company that continuously struggle and challenge toward the global best position with the core value and the core strategies.

Explanation

- Generic term of Via for build-up layer of build-up circuit board

- Build-up method builds up conductor layers by forming a conductor layer after a insulation layer, one by one; It allows to build VIA layers needed for each layer, mostly layering on both sides of the board one by one; applied for high density, highly integrated devices as it allows high speed signaling

- A specialized product applied for FPCB-Multi and RiGID-FPC products; allows to form more circuits than a same-sized product and realizes multi-function, high reliability and miniaturization

Main features

- A specialized product applied for FPCB-Multi and RiGID-FPC products; allows to form more circuits than a same-sized product and realizes multi-function, high reliability and miniaturization

- Applies mainly for connector cables and sub-boards; uses mainly supplementary boards for the soldering parts

- Realizes high density FPCB

- Compact design via a hidden VIA hole

Usage

- mobile module, LCD module, camera module ETC

- Wireless communication : Bluetooth

- Medical equipment /Military equipment

Specification

| ITEM | SPEC |

|---|---|

| Layers | 3~8 |

| Base Material | Polyimide or Polyester |

| Cover-lay | Polyimide or Polyester or Solder Mask |

| Thickness | 0.2mm~0.8mm |

| Line Width/Space | Normal Min, 0.07/0.07mm, Special Min. 0.06/0.06mm |

| Conductor | 1/3oz, 1/2oz, 1oz, ED or RA Copper |

| Surface finish | Electroless nikel immersion Gold, Direct Gold,soft gold, Hard Gold |

| Stiffener | Polyimide, Glass epoxy, Steel use stainless |

| Double coated tape | Coated Tape 3M 467 , 966 ,Sony D3410 , T4100 etc |

| Min. through hole diameter | Bit Drill Via Normal Min. 0.02mm Special Min. 0.150mm |

| Hole diameter tolerance | 10% |

| Solder resist | Photo Solder Resist, Polyimide flim |